Why a Solid PPAP Process is Essential for Success

Production Part Approval Process is a collaborative method that employs proven tools and techniques to systematically minimize risks before a product or service is launched.

Unlock Manufacturing Excellence: Mastering PPAP and SCR

July 5, 2024

Tags: PPAP

The automotive manufacturing industry relies heavily on a standardized process called the Production Part Approval Process (PPAP) to ensure that parts meet the highest quality

A Guide to PPAP: Understanding Production Part Approval Processes

The Production Part Approval Process (PPAP) is a standardized process in the automotive industry that helps to ensure that suppliers provide quality parts that meet

An Overview of the Production Part Approval Process and Part Submission Warrant

The Part Submission Warrant is a crucial document in the PPAP process that accompanies the submission of an original or revised part for production. This

Importance of Initial Process Studies for PPAP

Initial Process Studies used for to measure the consistency of the process or product performance based on specified design by reaching consistency of the product

Streamline your supply chain with Supplier Change Request!

Supplier Change Request (SCN) has major contribution at supply chain process. Which is requested by supplier when changes on defined product (design), process, materials which

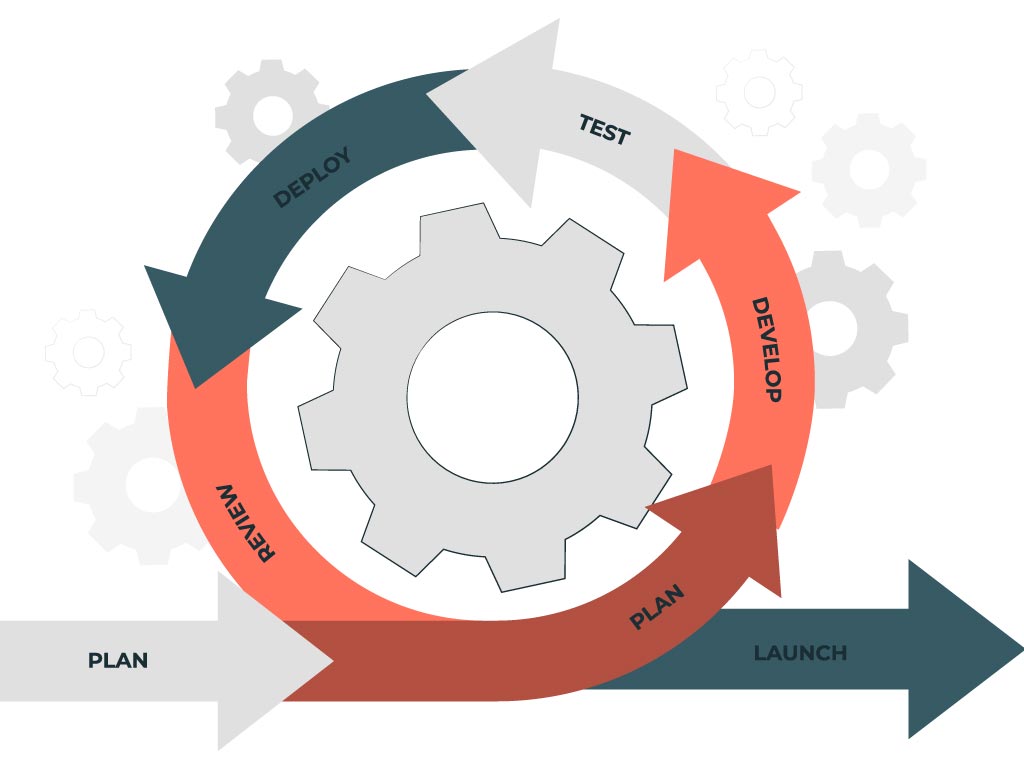

Stages in a Robust APQP Process

September 9, 2021

Tags: APQP, APQP documentation, APQP process, PPAP, PPAP Approval Process, PPAP documentation

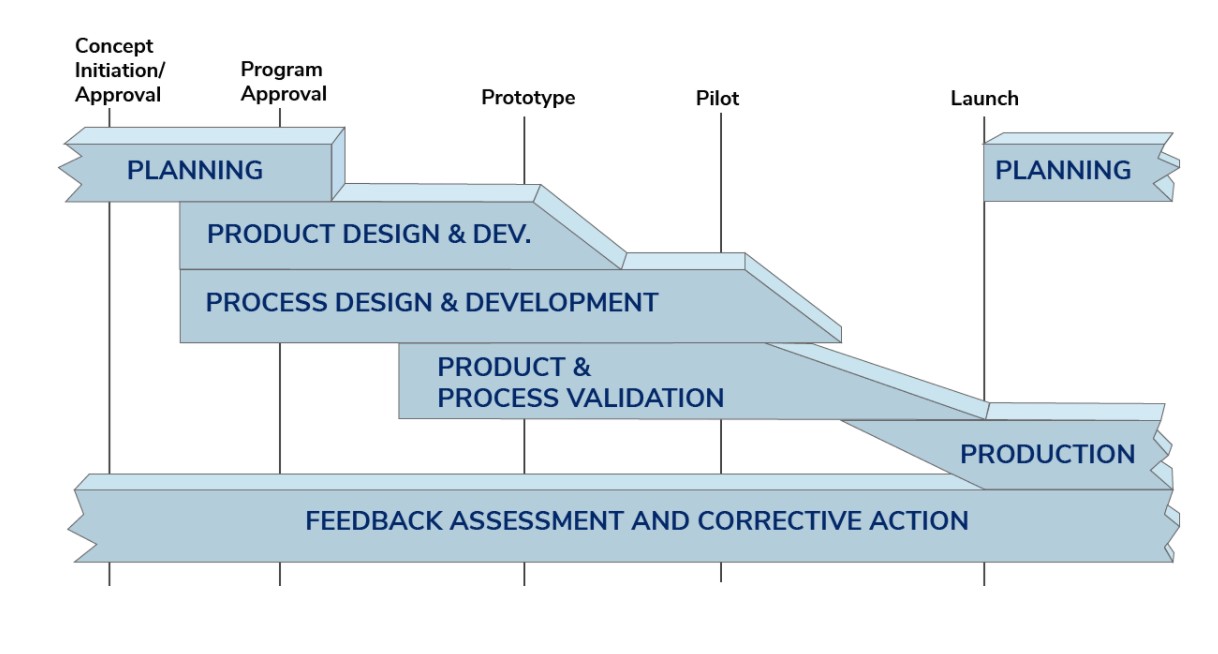

The APQP process consists of five stages: The flow of stages involved in the APQP are such that the output of one stage acts as