Who is a “SMART” Car Manufacturer?

How many automobiles do you think will be sold on an overall basis, across the world, in the coming year? Well, you missed the mark if you said anything less than 72.5 million which is the approximate figure projected by a recent Statista study!

How many automobiles do you think will be sold on an overall basis, across the world, in the coming year? Well, you missed the mark if you said anything less than 72.5 million which is the approximate figure projected by a recent Statista study!

While this represents a huge opportunity for an automobile manufacturer, it would also prove to be a daunting challenge with prospective buyers increasingly seeking the most fuel efficient, sleek, high performance car at optimum prices.

Here are a few quick pointers that automobile manufacturers are using to cut costs without compromising on the quality of the end product:

Creating multiple physical prototypes? No way!

The era of creating costly, traditional physical versions of trial automobile products are long gone! This is the era of 3D modeling which speeds up decision making with the ability to quickly set up alternative designs via 3D printing & enabling a detailed 360 degree review of virtual designs! 3D printing is basically a template to provide rendering services to help product developers create a digital image of a product to & visualize how it would look and feel in real life.

The advantage is also that this image can further be broken down into bits & each part can be separately tested to determine its functionality. Once the design team is satisfied with the model’s performance in a virtual world, an actual physical prototype can be created for further research.

Customer is the king? Yes indeed!

With the plethora of automobile offerings in the market, manufacturers are under ever greater pressure to meet customer’s never ending demand for additional features. With 3D modeling, vehicle designers can easily experiment with interior & exterior designs of the vehicle & virtually “test drive” it before the customer does so in real life!

They can also create multiple designs by altering colors, seating features, engine performance, parts, and materials before arriving at a final product that would find maximum acceptance from a prospective buyer segment.

Experiment with the different avenues of Car Manufacturing:

In case the vehicle manufacturing group utilizes 3D printing as a part of the beginning stages, they will have the capacity to try different things with different hues, trim styles, inside points of interest, and other configuration segments to figure out which will make the wanted finished result. They can likewise test the virtual vehicle on an advanced “test drive” to perceive how it will perform in different driving situations. Expensive car model generation just starts once it has been completely tried in a virtual situation.

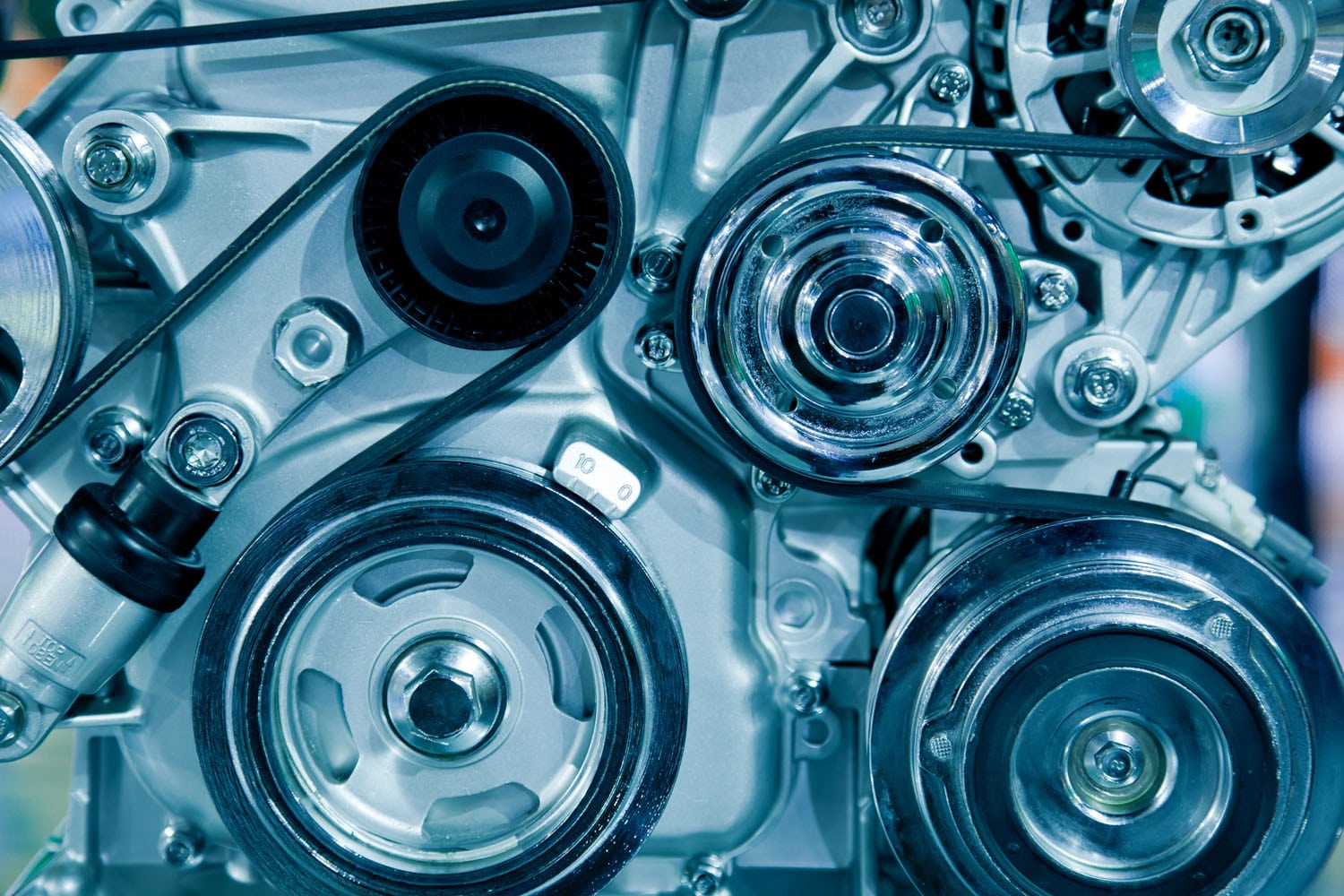

Thus using 3D printing, the car makers can try out an arrangement of components, parts, and materials for examining the potential accomplishment of every piece without spending a dime. For instance, as opposed to fabricate a totally new motor to check whether it will yield more noteworthy execution, they can make a virtual motor and afterward test and think about its execution.

3D Printing (Modeling) is now used for marketing too!

This effective 3D model can even be utilized by more than simply building the offering. The promoting division can utilize it for demos and presentations to create enthusiasm for another vehicle idea. A virtual 3D vehicle will have a much more prominent effect that a stagnant representation.

And finally, production!

It’s been test driven (virtually), checked for quality, performance, user acceptance and has finally been approved is now all ready to hit production! With automotive CGI & 3D printing, the biggest win so far as production is concerned is that it enables an automobile manufacturer to automate his machines on the assembly line to reproduce the product with utmost precision following exact templates. This in turn reduces chances of defective pieces being created and/ or production delays.