Thermal Analysis: Critical for Electronic Products During Design Phase

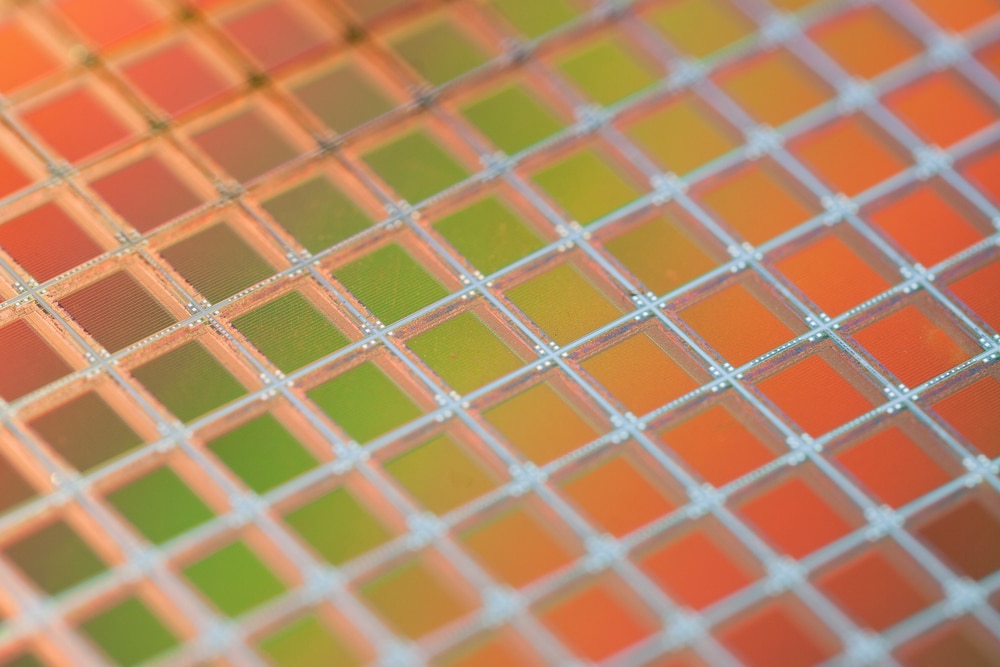

Increasing number, type and sizes of Electronic products entering into the market every day is causing need for better efficiency and durability of the product. Highly evolved consumers today are also aware of the technical nuances and reject products that get heated up and become dysfunctional. Considering this high rate of adoption & rejection of electronic products (mobile phones, laptops, tablets, portable devices, etc) manufacturers now give prominence to thermal analysis at the design stage.

Increasing number, type and sizes of Electronic products entering into the market every day is causing need for better efficiency and durability of the product. Highly evolved consumers today are also aware of the technical nuances and reject products that get heated up and become dysfunctional. Considering this high rate of adoption & rejection of electronic products (mobile phones, laptops, tablets, portable devices, etc) manufacturers now give prominence to thermal analysis at the design stage.

Heat dissipation is important requirement for all electronic products and should be considered early in the product development phase. During the design phase, performing thermal analysis using advanced CFD techniques helps to avoid product dysfunctionality by controlling overheating of the product. Most importantly the software also helps to predict temperature and air flow in and around the system, specifying fan details, amount of air to flow across the heat sink and the maximum temperature a component and withstand.

These predictions also enable resource efficient design modifications and virtual model creation on the basis of various tests. Appropriate selection of fan, position and sizes of air vents on the enclosure can also be estimated during the design phase.

There are tremendous short run to long run advantages of using thermal analysis during the design phase. Some of these have been listed below:

- Thermal analysis can provide the results for both natural and forced convection.

- Thermal analysis helps to show the flow curves of the air that pass through the systems and hence it helps to optimize the design.

- The software help in automating the thermal flow within the system with respect to the parameters provided and avoids the physicals prototypes to be made. Hence this in turn reduces the cost.

- It can generate reports such as Air velocity, Air temperature inside and outside the system. It also provides the temperature details of the heat source such as heat sink and the PCB components temperature in the system.

- The thermal analysis will help us to optimize design at a very early concept stage using the same CAD data file and can continue to reshape the design at the proto stage. Hence doing this analysis at an early stage prevents redesign at a later stage and also warranty repairs related to thermal.

Applications: The CFD software can be used in several area’s for example in HVAC (Heat, Ventilation and Cooling), Consumer products, Medical equipment’s, Electronics systems, and Power systems and so on.

CFD Tools: Ansys ICE PACK with Fluent solver, Autodesk Simulation CFD and Mentor Graphics FloTherm.