Stress Concentration Factor, an Important Parameter for the Safety of any Component

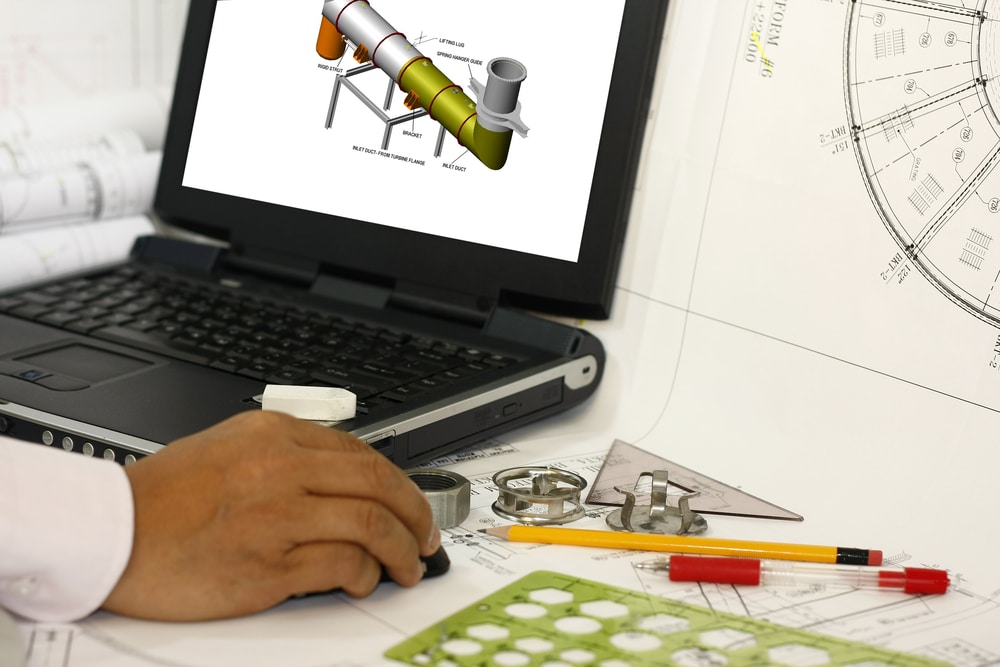

During the design phase of an engineering component, it is critical to consider safety parameters that define the efficiency of the mechanism. Basic stress analysis and calculations are performed at the initial phase assuming the components are smooth, having uniform profile and without irregularities. However in actual, all engineering components have at least minimal changes in section and/or shape like shoulders /steps on shafts, holes for oil, key ways and screw threads, which can impact on distribution of stress, some example figures are shown below.

During the design phase of an engineering component, it is critical to consider safety parameters that define the efficiency of the mechanism. Basic stress analysis and calculations are performed at the initial phase assuming the components are smooth, having uniform profile and without irregularities. However in actual, all engineering components have at least minimal changes in section and/or shape like shoulders /steps on shafts, holes for oil, key ways and screw threads, which can impact on distribution of stress, some example figures are shown below.

Mathematical analysis of stress concentration

Discontinuities in the components that lead to local increase of stress is referred to as stress concentration. Stress concentration factor (Kt), is a dimensionless factor which is used to quantify how concentrated the stress is in a material. It is thus defined as a ratio of the highest stress in the element to the reference stress. So it is important to analyze the component for stress concentration in order to have proper functioning of the component with safety. Otherwise the fabricated/manufactured component will not be fully functional with load; this might further hamper the balance of the system and cause severe effects.

To analyze stress concentration, we need to calculate the stress concentration factor, which is a critical parameter for the safety of the component.

Here we list down the important aspects of Stress Concentration and its factor. The below mentioned characteristics and recommendations will enable engineers to develop robust designs.

Characteristics:

- It is a function of the geometry / shape of the component. One should note that size or material has no role to play in design.

- It is a function of the type of loading applied to the part. Examples: axial, bending or torsional.

- It is a function of the specific geometric stress raiser in the part such as fillet radius, notch, or hole.

- It is always defined based on particular nominal stress

- It normally assumes a linear elastic, homogeneous, isotropic material

How to reduce the stress concentration:

A number of methods are available to reduce stress concentration in machine parts. Some of the most effective techniques followed by industry experts are listed below:

- Cross section of the component may change by providing a fillet

- Using an elliptical fillet

- Providing small notches instead of long one, when notch is unavoidable

- Using narrow notches rather than wide notches, if a projection is unavoidable

- Using stress-relieving grooves

How to prevent stress concentration:

If stress concentration is caused by a crack, then the best way to handle it would be to create a large hole right at the end of that crack. This drilled hole because of its rather large diameter is going to cause smaller stress concentration than a crack’s sharp end. While this surely works as a temporary solution, it should be rectified at the fastest opportune moment. A systematic checkup should be carried out to evaluate the damage caused by the crack so that proper prevention methods can be adapted.

The following images demonstrate the determination of Concentration Factor (Kt) for most frequently used shapes using