Machine Tool Automation: A Real Boon to the Manufacturing Sector

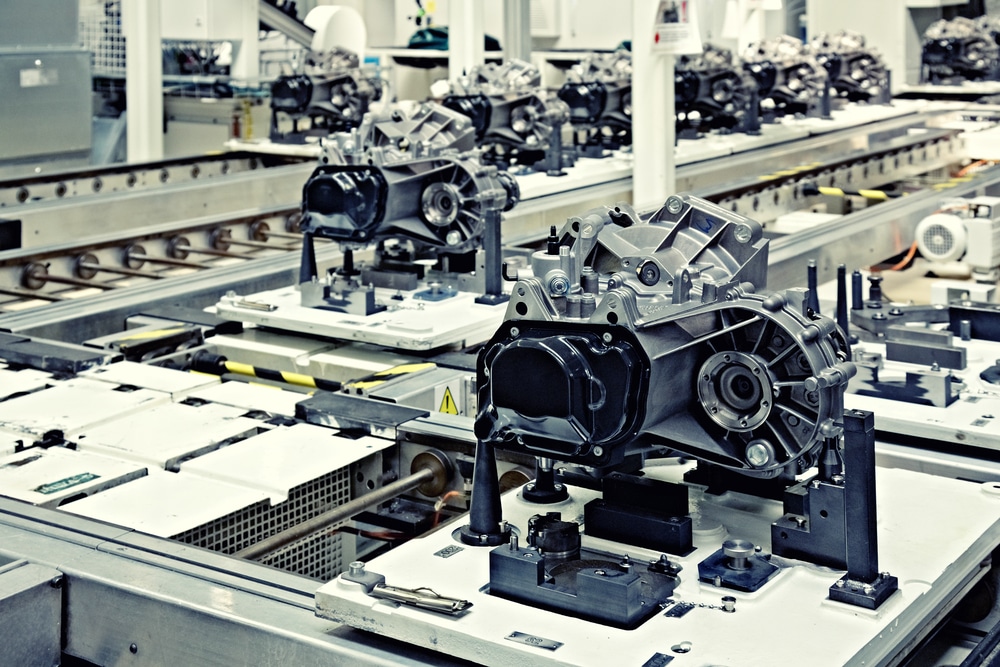

When key trends like precision and innovation dominate the market scenario, the challenges faced by manufacturers multiplies. Due to the increased production requirements and the need to compete with other manufacturers, it becomes crucial to include a computer aid in machine tools. In such scenario, technology’s gift of machine tool automation increases utilization & through put time and lowers cycle time & labor cost. Automation also helps to maintain parts quality and consistency. Various means including hydraulic, mechanical, pneumatic, electrical and electronic and computers, usually in combination enable automation that finds application in complicated systems, such as airplanes, modern factories and ships. The varieties of CNC machines such as grinding machines, Vertical/Horiz,ontal machining centers (VMC/HMC) which have multi axis capabilities enable to machine, precision components at higher productive rates.

When key trends like precision and innovation dominate the market scenario, the challenges faced by manufacturers multiplies. Due to the increased production requirements and the need to compete with other manufacturers, it becomes crucial to include a computer aid in machine tools. In such scenario, technology’s gift of machine tool automation increases utilization & through put time and lowers cycle time & labor cost. Automation also helps to maintain parts quality and consistency. Various means including hydraulic, mechanical, pneumatic, electrical and electronic and computers, usually in combination enable automation that finds application in complicated systems, such as airplanes, modern factories and ships. The varieties of CNC machines such as grinding machines, Vertical/Horiz,ontal machining centers (VMC/HMC) which have multi axis capabilities enable to machine, precision components at higher productive rates.

The latest trend in manufacturing has caused creative destruction with the use of Collaborative Robots. Robots traditionally used in the automotive sector, have now been accepted across sectors like Electronics, Pharmaceutical, etc. The technology has penetrated and has expanded opportunities and application for small manufacturers.

The real benefits of Machine Tool Automation range extensively. Below mentioned are a few key reasons why all sectors are latching onto it:

- Delivers competitive advantage for companies by enhancing productivity

- Enables to lower operational variability, thus delivering consistent and reliable products

- Contributes to minimize the hazard risks involved in the manufacturing process

- Is a paramount factor for lowering cost of human labor

Target Sectors:

- Automotive part manufacturing

- Aerospace/Shipping components manufacturing

- Medical Equipment’s manufacturing

- Other mid to high volume components manufacturing

With customer centric processes and systems, its needless to say that machine tool automation will do perfect justice to the deliverables. The well-known Special Purpose Machines (SPM) adopt intelligence in working and support uninterrupted production of superior quality. The concept belongs to the future and promises to do a lot of good to the sector.