Faster And Cost Effective As Built Drawings

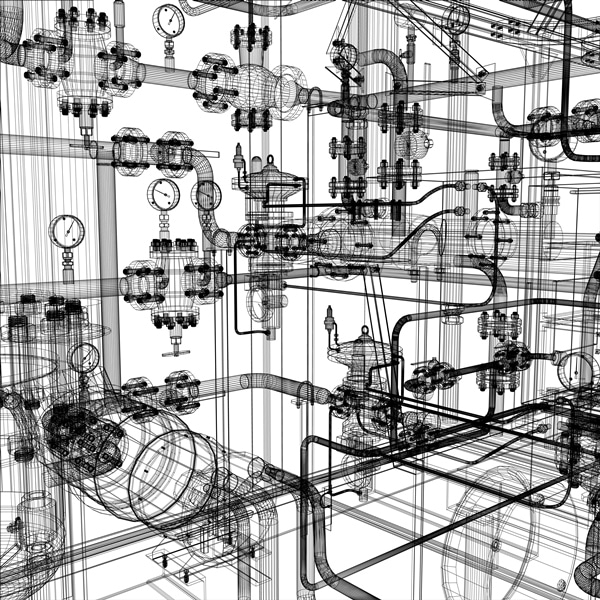

As Built drawings are some of the most important components of any construction project. These are revised drawings of a site that will be detailed for displaying the refinements or variations made on an original design. Commonly the As Built drawings are developed by the contractor. All throughout the total duration of the building project, a contractor needs to determine how the existing structure appears to be as it is an essential aspect of applying adaptations to that particular development project. Any changes that are made on the actual structure such as a piping system will be documented fully and comprehensively on the As Built drawings. Notes, drawing and modifications will be featured in the As Built drawings that will in turn help to prevent unnecessary interruptions with the main construction process.

As Built drawings are some of the most important components of any construction project. These are revised drawings of a site that will be detailed for displaying the refinements or variations made on an original design. Commonly the As Built drawings are developed by the contractor. All throughout the total duration of the building project, a contractor needs to determine how the existing structure appears to be as it is an essential aspect of applying adaptations to that particular development project. Any changes that are made on the actual structure such as a piping system will be documented fully and comprehensively on the As Built drawings. Notes, drawing and modifications will be featured in the As Built drawings that will in turn help to prevent unnecessary interruptions with the main construction process.

Use of technology for creating As Built drawings.

The use of some advance technology today has eliminated the necessity for the site engineers to make multiple field trips and collect data for As Built drawings. Today, producing As Built drawings is simpler, less time-consuming and more importantly cost effective. Compared, to traditional methods of utilizing the instrument, measuring tapes & sketch pad etc. which required accurate efforts to place tie-in points into the 3D model for modifications in the existing Plants, technology today offers advanced laser techniques that help create more precise and reliable drawings.

Change in the nature of piping systems over the years

Over time, the Piping Systems for Plants have also evolved. In the past, the Piping Systems remained unchanged and were more accessible for the field technician to hand sketch field isometric drawings. Today, Piping Systems have become more complex and prone to various hazards. The technicians mostly need to place themselves in uncertain situations to obtain the exact measurements. Often they need to make multiple site trips due to drawbacks of this method like missing dimensions, manual data errors and inaccurate recordings. In most cases the time taken to collect the field data forms a significant factor in increasing the overall engineering costs.

Combined risk of various hazardous conditions and lack of accurate access to the Plant, triggered the need for advanced technology for field survey using laser surveying scanners (like FARO Laser Scanner).

The benefits of using laser technology for piping systems

In the current scenario, the use of these laser techniques helps to facilitate:

- Enhanced field data, easy access to complex Plant or Piping Systems

- Quicker 3D As Built drawings from scratch can be developed

- Easier to build accurate complex Piping Systems

- Faster turn-round for a wide range of Plants and Facilities

With such techniques gaining prominence it is easier to do retrofit work or modifications on the existing Plants. The simplified usage also contributes towards efficiency of the field engineering team, design engineering experts and drafting specialists. The resulting data allows engineering team to extract more as-built information than before, ensuring confidence within the design team. Apart from providing accurate data, the techniques also ensure maximum safety, cost saving for customers and field engineers.

With the usage of As Built drawings, the construction process has been rendered much easier in the modern times. Also known as as-constructed drawings or as-installed drawings, they have greatly improved the standards of piping engineering service that is delivered by various professional experts in this field.